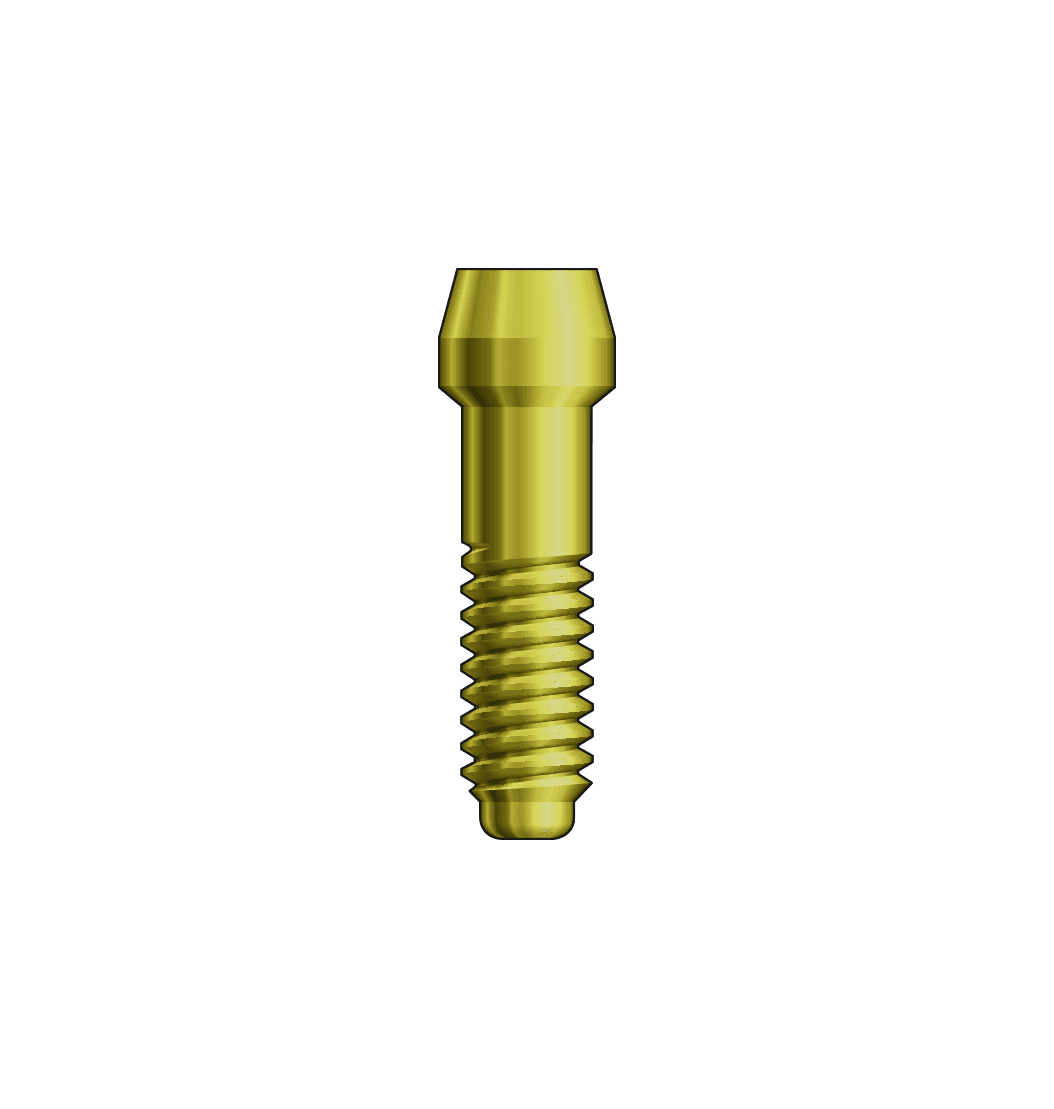

Titanium Implant Screw

The use of titanium in medical implants has revolutionized the field of orthopedic and dental surgery. One of the most significant applications of titanium is in the manufacture of implant screws, which are used to secure implants in place. Titanium implant screws have become the preferred choice among surgeons due to their unique combination of properties, which make them ideal for use in the human body.

One of the primary advantages of titanium implant screws is their high strength-to-weight ratio. Titanium is a strong and lightweight metal, which makes it possible to manufacture screws that are both durable and minimally invasive. This is particularly important in orthopedic surgery, where the goal is to restore mobility and function to the affected joint or bone. Titanium implant screws are able to withstand the stresses and strains of weight-bearing joints, while also being gentle on the surrounding tissue.

Another significant benefit of titanium implant screws is their corrosion resistance. Titanium is highly resistant to corrosion, which makes it an ideal material for use in the human body. The body’s fluids are highly corrosive, and other metals may react with these fluids, leading to the release of toxic ions. Titanium, on the other hand, is able to withstand the corrosive environment of the body, reducing the risk of adverse reactions.

In addition to their strength and corrosion resistance, titanium implant screws are also highly biocompatible. Biocompatibility refers to the ability of a material to be accepted by the body without causing an adverse reaction. Titanium is highly biocompatible, and it has been shown to integrate well with bone tissue. This is due in part to the unique surface properties of titanium, which allow it to form a strong bond with the surrounding bone.

The use of titanium implant screws has a number of clinical applications. In orthopedic surgery, titanium screws are used to secure joint replacement implants, such as hip and knee replacements. They are also used to treat fractures, where they are used to stabilize the bone and promote healing. In dental surgery, titanium screws are used to secure dental implants, which are used to replace missing teeth.

The manufacturing process for titanium implant screws is highly complex and involves a number of specialized techniques. The screws are typically manufactured using a combination of machining and forging, which allows for the creation of complex shapes and geometries. The surface of the screw is also treated to create a texture that promotes bone integration.

One of the key challenges in the manufacture of titanium implant screws is ensuring their sterility. Implant screws must be completely free of contaminants and microorganisms, which can cause infection and other complications. To address this challenge, manufacturers use a variety of sterilization techniques, including gamma radiation and ethylene oxide sterilization.

In conclusion, titanium implant screws have revolutionized the field of orthopedic and dental surgery. Their unique combination of strength, corrosion resistance, and biocompatibility makes them an ideal material for use in the human body. As the field of medical implants continues to evolve, it is likely that titanium implant screws will play an increasingly important role in the treatment of a wide range of medical conditions.

What are the benefits of using titanium implant screws?

+Titanium implant screws offer a number of benefits, including high strength-to-weight ratio, corrosion resistance, and biocompatibility. They are also able to integrate well with bone tissue, reducing the risk of adverse reactions.

What are the clinical applications of titanium implant screws?

+Titanium implant screws have a number of clinical applications, including orthopedic surgery, where they are used to secure joint replacement implants and treat fractures. They are also used in dental surgery to secure dental implants.

How are titanium implant screws manufactured?

+Titanium implant screws are manufactured using a combination of machining and forging, which allows for the creation of complex shapes and geometries. The surface of the screw is also treated to create a texture that promotes bone integration.

The future of titanium implant screws is likely to involve the development of new technologies and materials that can further improve their performance and biocompatibility. One area of research that holds particular promise is the development of nanostructured titanium surfaces, which have been shown to promote bone integration and reduce the risk of adverse reactions.

Another area of research that is likely to have a significant impact on the development of titanium implant screws is the use of 3D printing technologies. 3D printing allows for the creation of complex geometries and shapes, which can be used to create customized implant screws that are tailored to the individual patient’s needs.

In terms of the potential risks and complications associated with titanium implant screws, it is worth noting that while they are generally considered to be safe and effective, there are some potential risks to be aware of. These include the risk of infection, which can occur if the screw becomes contaminated during the manufacturing or implantation process. There is also a risk of adverse reactions, which can occur if the patient has a sensitivity to titanium or other materials used in the screw.

Overall, titanium implant screws have revolutionized the field of orthopedic and dental surgery, offering a number of benefits and advantages over traditional materials. As the field continues to evolve, it is likely that titanium implant screws will play an increasingly important role in the treatment of a wide range of medical conditions.

According to a recent study published in the Journal of Orthopedic Research, the use of titanium implant screws has been shown to reduce the risk of complications and improve patient outcomes in orthopedic surgery. The study found that titanium screws were associated with a lower risk of infection and adverse reactions, and that they were able to promote better bone integration and healing.

In conclusion, titanium implant screws are a highly effective and versatile material that has revolutionized the field of orthopedic and dental surgery. Their unique combination of strength, corrosion resistance, and biocompatibility makes them an ideal material for use in the human body. As the field continues to evolve, it is likely that titanium implant screws will play an increasingly important role in the treatment of a wide range of medical conditions.

Step-by-Step Guide to Titanium Implant Screws

- Material selection: The first step in the manufacture of titanium implant screws is the selection of the raw materials. This involves choosing a high-quality titanium alloy that meets the required standards for strength, corrosion resistance, and biocompatibility.

- Machining and forging: The next step is to machine and forge the titanium alloy into the desired shape and geometry. This involves using a combination of computer-controlled machines and traditional forging techniques to create a screw that meets the required specifications.

- Surface treatment: Once the screw has been machined and forged, the surface is treated to create a texture that promotes bone integration. This involves using a variety of techniques, including etching, polishing, and coating, to create a surface that is optimized for bone growth and healing.

- Sterilization: The final step is to sterilize the screw to ensure that it is free from contaminants and microorganisms. This involves using a variety of sterilization techniques, including gamma radiation and ethylene oxide sterilization, to ensure that the screw is safe for use in the human body.

The use of titanium implant screws has a number of benefits and advantages, including high strength-to-weight ratio, corrosion resistance, and biocompatibility. They are also able to promote bone integration and healing, reducing the risk of complications and improving patient outcomes. As the field of orthopedic and dental surgery continues to evolve, it is likely that titanium implant screws will play an increasingly important role in the treatment of a wide range of medical conditions.

Pros and Cons of Titanium Implant Screws

Pros:

- High strength-to-weight ratio

- Corrosion resistance

- Biocompatibility

- Promotes bone integration and healing

- Reduces the risk of complications and improves patient outcomes

Cons:

- High cost

- Limited availability

- Potential risk of adverse reactions

- Potential risk of infection